AIM Intelligent Machines

About AIM Intelligent Machines

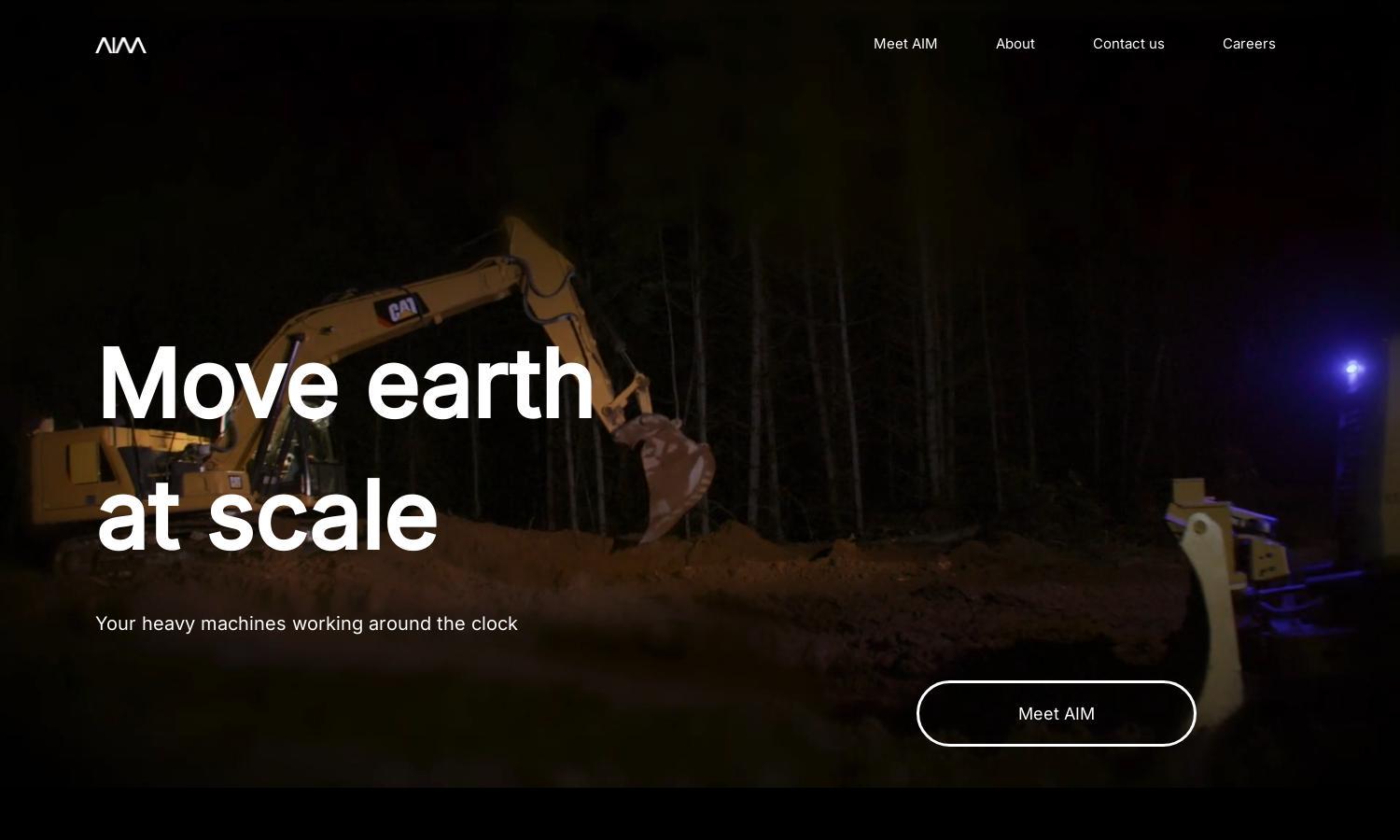

AIM Intelligent Machines revolutionizes construction and mining by automating existing heavy equipment. Users benefit from enhanced safety and operational efficiency thanks to its advanced retrofit technology, which maintains manual control. With 0 accidents recorded, AIM empowers workers to focus on advanced site planning and management, alleviating the risks of hazardous tasks.

AIM Intelligent Machines offers tailored consultations for businesses looking to automate their equipment. Each plan is designed to cater to various operational needs, ensuring users gain maximum value from upgrades. By enhancing safety and productivity, AIM facilitates significant returns on investment for all clients through its innovative solutions.

AIM Intelligent Machines features an intuitive interface designed to streamline user experience and engagement. The layout allows quick navigation through services, consultation booking, and product information, ensuring a user-friendly experience. With visual aids and easy access to resources, AIM enhances efficiency in connecting users with cutting-edge automation technology.

How AIM Intelligent Machines works

Users begin their journey with AIM by consulting with a team of experts to assess their existing heavy machinery. The AIM system is then retrofitted to enable autonomous operations while preserving manual controls. Users can monitor tasks remotely and receive real-time analytics, while the equipment runs safely without a direct operator, ensuring higher productivity levels.

Key Features for AIM Intelligent Machines

Autonomous Retrofitting Technology

AIM Intelligent Machines' autonomous retrofitting technology transforms conventional heavy machinery into fully automated equipment. This unique feature enhances operational efficiency, enabling machines to function around the clock without human operators while maintaining safety, empowering businesses to maximize their investment in existing assets.

360-Degree Safety System

The 360-Degree Safety System offered by AIM Intelligent Machines ensures unparalleled protection for ground staff and equipment. This multi-layered safety protocol prevents accidents and minimizes risks in hazardous environments, allowing companies to operate safely and confidently with their automated machines.

Upskilling Workforce Solutions

AIM Intelligent Machines focuses on upskilling the workforce by allowing employees to shift from operational roles to advanced site planning and analytics. This unique approach not only enhances career opportunities for workers but also boosts overall productivity by optimizing resource management and machinery usage.